In a memorable scene from ‘90s sci-fi flick “The Fifth Element,” the hand of an alien creature is recovered from a destroyed spaceship. Using DNA extracted from the hand, scientists reconstruct the creature’s entire body through a printer, organ by organ, layer by layer.

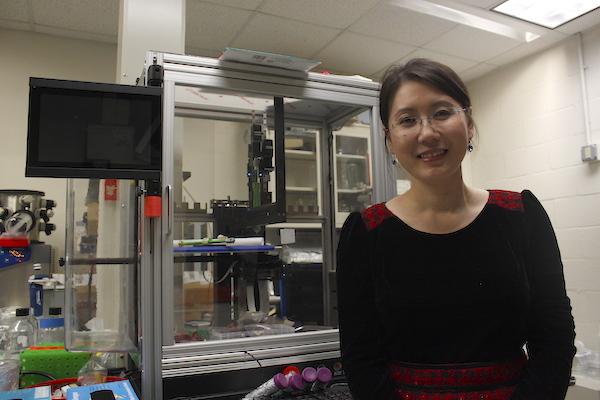

Set in the 23rd century, the film is futuristic. But bioengineer Lijie Grace Zhang, who runs a laboratory for nano-medicine and tissue engineering at GW, said the organ printing in “The Fifth Element” isn’t too far from reality.

In early October, Zhang, an assistant professor, received the 2014 Director’s New Innovator Award from the National Institutes of Health, which funds innovators with potentially high-impact ideas, for her five-year project: “A Novel 3-D Bioprinted Smart Vascularized Nano Tissue.”

Translation?

As one of this year’s 49 New Innovators (and the first from GW to be recognized), Zhang was awarded $2,287,500. With the funds, she’ll look to use 3-D printers to create tissue that replaces damaged parts of the human body, in a lab right on campus.

Though her research – and the field of tissue engineering itself – is still in their early stages, Zhang hopes to print entire organs, as complex as lungs and even a human heart, in her lifetime.

“For the organ regeneration, I’m very optimistic about that, but there is a long way,” Zhang said. “It’s a useful product, it can be used to improve human health … there is already a lot of progress.”

And though it may sound like something out of a sci-fi – maybe even horror – movie, her project is very real.

As Zhang led me through her crowded Tompkins Hall laboratory, the tables seemed to overflow with trays, clinking test tubes and the whir of complex machinery, enough to baffle even a bioengineer.

But as Zhang explained, there is a method to the madness.

Zhang and the seven students (six Ph.D. candidates and one full-time master’s student) who conduct research in her lab order packages of donated human stem cells from Texas A&M University. Stem cells are ideal, since they have the potential to differentiate into multiple types of cells and tissues.

Once the stem cells arrive, the team uses them to replicate human tissue through one of the four 3-D printers housed in the lab, which divide 3-D models into two-dimensional “slices” and replicate each, layer by layer.

The complex process can be explained quite simply: We’ve built the machines. Now, they’re building us.

But to work toward the goal of printing human organs, Zhang and her team of researchers must solve the problem of printing vascular tissue, like veins and arteries, which carry blood through the body, rid cells of waste and supply cells with nutrients.

Because of the density of vascular tissue, it is difficult to engineer a replica that allows blood to circulate through the entirety of the structure.

“Specifically, we’re working on vascularized bone tissue,” Zhang said at the lab. “Vascularization right now is the biggest challenge in tissue organ regeneration. If we cannot overcome that problem, the organ regeneration is infeasible.”

Without functional vascularized tissue, 3-D printed organs would be nothing more than empty structures.

“It’s easy in the lab, we can fabricate a shape, like, maybe, a lung, a kidney, a heart. But the challenge is making them functional, because they’re not just shapes,” Zhang said.

GW’s School of Engineering and Applied Science isn’t the only institution making waves in the field of tissue regeneration.

At the Wyss Institute for Biologically Inspired Engineering at Harvard University, researchers have engineered 3-D tissue models that contain blood vessels and multiple cell types, which they hope to use to test the effects of drugs. Similar programs are at Boston University, Rice University and M.I.T.

Anthony Atala, the director of the Wake Forest Institute for Regenerative Medicine, made headlines with a TED Talk he gave in 2009, during which he printed a human kidney (albeit not a functional one) for the audience.

And further outside the higher education sphere, 3-D printing companies like Conformis print more than 1,000 personalized knee implants a year.

Zhang’s lab has its own revolutionary focus: Combining the biomaterial-based and cell-based methods of research to control stem cell differentiation. But she said another important aspect of her lab is interacting with students.

Zhang meets individually with the students who work in her lab on a weekly basis and encourages them to share their own ideas. If their ideas fit with Zhang’s research, the students may use the lab to conduct their own experiments.

Ph.D. student and lab manager Nathan Castro, who spends between 50 and 60 hours a week in the space, used the opportunity to propose a new system to produce nano-spheres that will make 3-D scaffolds more bioactive, inducing stem cells to differentiate.

“More established labs, they already have a set of projects and experiments where going in, you as a new student don’t really have that flexibility to sort of design your own experiments,” Castro said. “[Zhang] gives us the opportunity to pursue our own ideas.”

Robert McGrane, a master’s student who works alongside Castro, has brought his interest in cartilage engineering to the lab.

A former business major, he now works in the lab on a bone analog for breast cancer metastasis, claiming he has “personal skin in the game” since a close family member is suffering from a similar disease, multiple myeloma.

“I hadn’t considered engineering prior, but it just seemed a lot more interesting,” McGrane said on a break from his lab work. “I thought that, honestly, putting my talents and what-not into this would be a much better-served purpose.”

This semester, Zhang’s lab has doubled in size. And though decades of further research rests on her shoulders, Zhang is optimistic about the future of the field.

“We are doing a very innovative, a very exciting research project that can improve the human health not only for vascularized tissue but for organ regeneration,” she said. “I’m very excited, I’m very glad and really honored.”