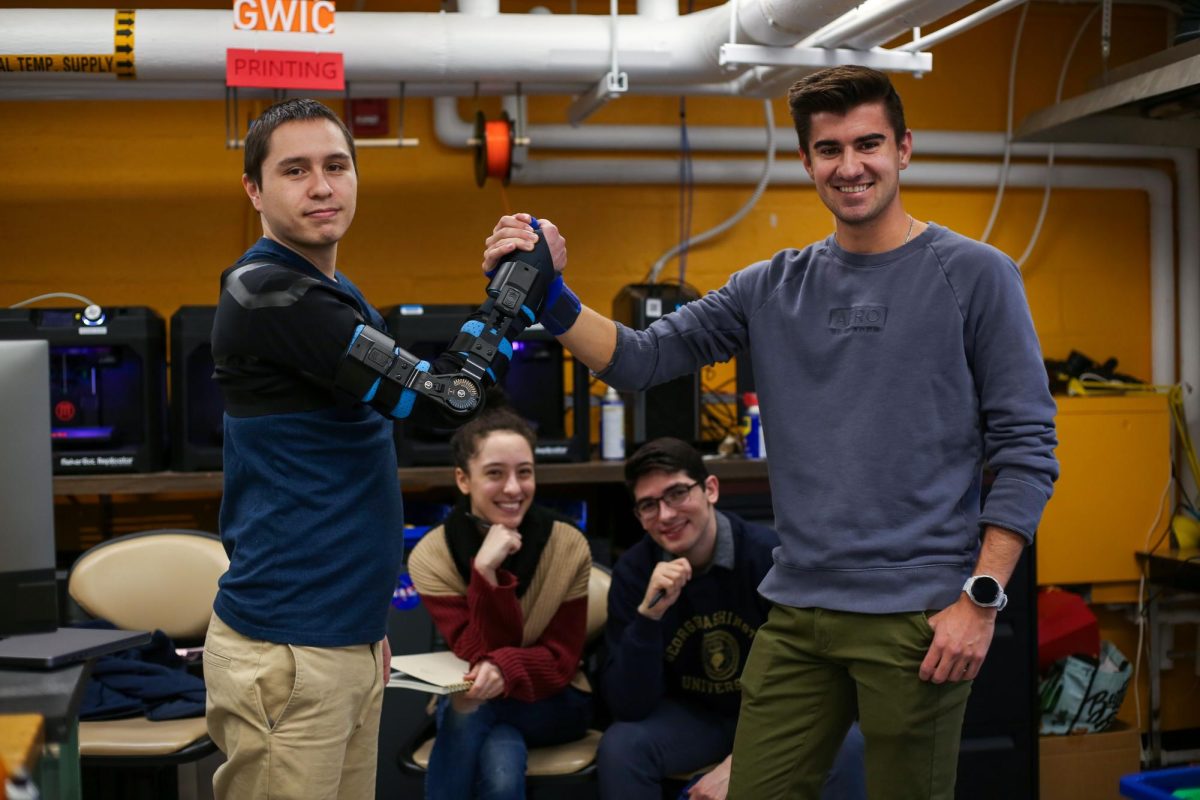

A group of mechanical engineering students are designing an arm brace for a veteran and Paralympian, which they will build next semester and complete in March.

The group is customizing an arm brace for Robbie Gaupp — a veteran who served in the U.S. Army for nine-and-a-half years and now competes in Paralympic skeleton and track and field — to wear when competing and in everyday life. This year’s group will adjust the brace, which a different group of GW Engineering students designed last year, to make the design less stiff, fold 90 degrees and stay in place on his arm.

Gaupp said he sustained a right brachial plexus injury — an injury in the nerves that send signals from the spinal cord to the shoulder, arm and hand — in 2008 when he was running at full speed with little lighting during a joint operations mission for Border Patrol. He said he tried to move a low-lying branch out of his path, which knocked him off his feet and dislocated his right arm into his chest cavity. He then lost sensation from the shoulder down, aside from a sensitive area in his elbow and still struggles to move the arm despite several surgeries and rehabilitation, he said.

Gaupp, a lifelong athlete, said he has competed in Paralympic track and field, archery, skeleton and seated volleyball, after initially giving up on sports following his injury. He said he played for the Texas Outlaws, a professional football team based in Austin, Texas, before his injury.

“I just needed to show my ability over my disability,” he said.

Gaupp said a representative from Quality of Life Plus — a nonprofit organization that partners with college students studying STEM fields to design and build assistive technology for disabled veterans — approached him around 2019 at one of his skeleton events to invite him to join their program. He said he ultimately decided to join, which is how he connected with GW students two years ago. Gaupp said he hopes that this brace helps him gain greater functionality.

“I want them to know that what they are doing is something beyond them and is amazing,” Gaupp said. “Because where they just think are helping out with a brace or this or that, they’re helping out with a person’s, basically, livelihood.”

Jade Greenberg, a senior majoring in mechanical engineering, said the team is developing the brace for Gaupp as part of their senior capstone — a two-semester sequence where mechanical engineering seniors design and build a product for a real client — after the mechanical engineering department connected the seniors to Quality of Life Plus and Gaupp to design and produce a project.

“When you work on technology for somebody that has a disability, whether that’s accessibility or personalized solution that fits their body, I felt like I was I was hoping to learn a lot from the client themselves in how they learn to work with their disability and what solutions they might have already come up with,” Greenberg said.

William Gay, a senior majoring in mechanical engineering, said the team met with Gaupp last month to hear his story and needs for the brace and take measurements of his body to specifically fit his brace. He said the team is using some existing materials, like compression sleeves, and computer-aided design software, which allows them to design and 3D print other parts of the brace.

He said this semester, the team has focused on gathering information about Gaupp’s needs, communicating with Gaupp and making sketches and designs before they build the brace next semester.

“I feel like we did a good job of understanding exactly what he’s looking for but meeting with him and looking at previous designs to figure out what exactly we need to build for next semester,” Gay said.

Matthew Coughlin, a senior majoring in mechanical engineering, said the group will change the brace’s initial design from wires that could be tightened and loosened to adjust the arm’s angle, to a ratcheting tool, which can spin in one direction and lock in place, meaning while the brace is on, the arm can be increased in increments. He said the new design will allow the elbow to bend to a 90-degree angle, compared to the previous design only moving about 20 degrees.

He said the team is currently in the prototyping stage and anticipates spending the next two months creating prototypes and collecting feedback from Gaupp to further improve the design. He said the group expects to have the final product completed in March.

“We think this design is pretty effective to what he wants because besides the 90 degrees, this would actually allow him to customize different ranges of motion that maybe he didn’t think was possible,” Coughlin said.

Anthony Costello, a senior majoring in mechanical engineering, said the group is looking to make the construction of the brace simple and easy to repair. He said they want the brace to be easy to repair with parts readily available on the market so that if Gaupp falls and breaks a part of the brace during a sporting event, it won’t inhibit his quality of life. He said the project has shown him that engineers can make real-world changes right away.

“Just having this other aspect of having a directly impactful design or like the terms of a directly impactful project really makes me feel more involved in a sense, rather than working with another company,” Costello said.

Steve Shooter, a professor of mechanical and aerospace engineering, said one of the most challenging skills of this group’s capstone project to master is not necessarily the technical aspect, but communication. He said while engineering typically focuses on technology, math and science, this project is teaching students how to communicate to meet specific client needs.

“A big thing is, that these students learn about, is how to focus on customer needs, kind of what we call ‘user-centric design,’” Shooter said. “Thinking about, ‘How is this person actually going to use it? How is this going to benefit them?’”