Students and faculty are manufacturing medical equipment for D.C. Fire and Emergency Medical Services as frontline workers scrape together resources to battle COVID-19.

Alexander Cullen, a training coordinator at GW’s Department of Emergency Medicine Training Center – which offers educational programming in emergency life support – said the team has delivered nearly 1,500 pieces of medical equipment since April 15 consisting of face shields and breathing machine adapters that protect paramedics treating patients inflicted with the virus. Cullen said officials began working with FEMS the first week of April to prevent breathing machines hooked to patients from passing the virus to on-duty paramedics.

“When it turned out that we had a solution that we could prototype, design ourselves and print in-house and supply in quantity within a couple of days, it meant that the fire department was able to go back to using the appropriate patient care methods while remaining safe,” he said.

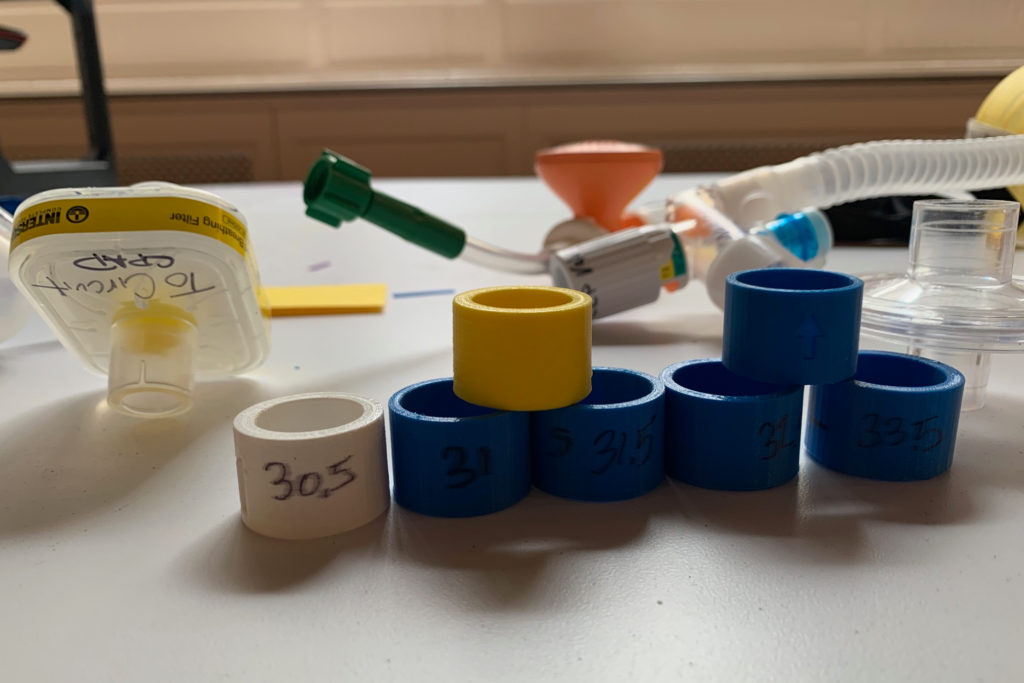

Douglas Buchanan, the chief communications officer of FEMS, said D.C. paramedics use the small plastic adapters to connect filters to Continuous Positive Airway Pressure machines that inject oxygen and pressure into patients’ lungs through a mask. The machine requires filters to capture germs carrying COVID-19 before they reach the surrounding atmosphere after patients exhale through their masks, he said.

Cullen said the team has been distributing face shields to provide masks extra protection from exposure to droplets from sneezes, coughs or any “respiratory process.”

“Being unprepared because of a lack of proper equipment, whether through oversight or a lack of ability to purchase is incredibly frustrating, especially when it’s a small piece of plastic that could make you much safer,” Cullen said.

The University’s partnership with FEMS follows a slew of University-wide COVID-19 relief efforts, including drive-thru testing sites and housing for health care workers.

Cullen said the team has sent more than 1,000 adapters and 450 face shields to FEMS since it first began delivering equipment April 15 and has now stocked FEMS and other local fire departments like Arlington County with more than 250 percent of their original needs. The team has shifted its focus to prototyping additional viral filters for CPAP machines and manufacturing virus testing swabs from 3D printers, he said.

“It’s just about making sure that the people that are doing the work on the front lines right now stay safe,” Cullen said.

He said the team had to measure the amount of “dead space,” or unnecessary volume, within each viral filter’s ventilatory circuit that connects the patient to the ventilator so the adapters could have a tight fit on the machine.

Cullen said he works another job as a paramedic in which he must wear protective equipment like N95 masks to avoid infection. He said his experience in the job helped him understand the urgency in distributing these adapters to the fire department to keep frontline workers safe.

“As someone who’s wearing an N95 and going into homeless shelters and nursing homes for my daily job, knowing that you couldn’t safely use CPAP to manage these people, and that’s the standard of care, was something that I don’t think any of us were really OK just accepting at face value,” he said.

Cullen said he has been working on the project with volunteers from the School of Engineering and Applied Sciences and the Corcoran School of the Arts and Design along with Sylvain Guiriec, an astrophysics professor who volunteered to help manufacture the swabs.

Cullen said the Corcoran School has allowed the group to use its 3D printers and has donated 3D printing filament and “durable materials” to aid the process of printing swabs and adaptors. He said he created a GoFundMe page that has raised $5,000 as of Sunday for the team to afford more materials, he said.

“We have an astrophysics professor, an art and sculpture professor, an engineering student and a paramedic that are all working on one project cohesively for the purpose of just trying to help the community that we live in,” Cullen said.

Buchanan said the adapters GW has been delivering were in short supply because of increased demand for protective machinery during the pandemic. He said GW and the local nonprofit Nova Labs, also delivering adapters to FEMS, have been able to compensate for that demand with their deliveries.

“We are now confident because of the work that GW did and their insight in realizing our need that we are now able to do everything that we’re able to do to protect our members on the numerous calls they respond to each day,” he said.

Buchanan said the fire department paramedics who work 24-hour shifts “are in the belly of the beast” in their fight for their patients’ safety amid the pandemic. He said the fire department’s partnership with the University has given first responders the protection they need to safely perform their jobs.

“What GW has been able to provide us is that sense of security for our members to ensure that they can do their jobs without also becoming infected themselves, which in thus protects their fellow team members on the firetruck, those within the firehouse and as importantly their families back at home,” he said.